Reference Dosimetry for Frozen Healthcare Products

Overall requirements, use of surrogate materials and application of reference dosimetry during routine gamma irradiation

Ensuring that the correct radiation dose is delivered to a healthcare product is essential. Frozen products surrounded by high density materials such as ice packs or dry ice during the irradiation processes present a unique challenge. Many commonly used dose measuring or dosimetry methods are influenced by temperature, making the placement of a dosimeter in the volume of frozen material impractical.

Internal dose can be determined for the material volume by empirically deriving a ratio between routine-monitoring dosimetry position (reference position) and the minimum and maximum absorbed dose positions in a surrogate material. The use of a reference dosimeter monitoring location eliminates the need to compensate for the difference in dosimeter response due to temperatures.

A surrogate material which mimics the density and packaging distribution of the product or actual material that will not be distributed to market, at ambient temperature, can be used to establish the dose ratios (and resulting correction factors), thus avoiding temperature compromise to the dosimeter results.

Once a reference ratio has been determined, a routine dosimetry system can be used to measure the reference dose. The minimum and maximum doses can then be calculated by applying the established correction factors to the measured reference dose.

Overall Requirements

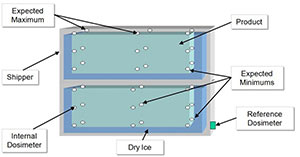

The overall purpose of a reference dose mapping study is to determine the ratios from the reference dosimeter position to the minimum dose delivered to the product (reference to minimum) and from the reference dosimeter position to the maximum dose delivered to the product (reference to maximum). To capture the minimum and maximum delivered dose to the product, dosimeters must be placed throughout the surrogate product where the minimum and maximum delivered doses are expected to occur.

Dosimeters should not be placed in or on the surrogate dry ice or ice packs as dosimeter response to these areas do not reflect the dose being delivered to the actual product. The reference dosimeter may be placed anywhere in the product load on the outside of a shipper. It is recommended to place the reference dosimeter in a location that is easy to access during routine production.

Example Dose Mapping Dosimeter Placements

Application of Reference Dosimetry During Routine Gamma Irradiation

The reference ratios determined through the dose mapping study are used to calculate the dose range that must be delivered to the reference dosimeter in order to achieve the required minimum and maximum dose to the product (internal dose) during routine production. The same ratios are later used during routine production to calculate the dose delivered to the product based on the reference dose dosimeter.

Calculation of Reference Ratios:

- Avg Reference Dose / Avg Min Internal Dose Delivered = Reference to Minimum Ratio

- Avg Reference Dose / Avg Max Internal Dose Delivered = Reference to Maximum Ratio

Calculation of Dose to Reference Dosimeter:

- (Reference to Min Ratio)(Required Min Internal Dose) = Minimum Reference Dose

- (Reference to Max Ratio)(Required Max Internal Dose) = Maximum Reference Dose

Calculation of Delivered Dose During Routine Production:

- Reference Dose / Reference to Min Ratio = Minimum Internal Delivered Dose

- Reference Dose / Reference to Max Ratio = Maximum Internal Delivered Dose

Surrogate Materials

Dose delivered to the product during preliminary dose mapping studies cannot be guaranteed since the external dose needed to achieve the required internal dose is not known prior to completion of the study. Therefore, a surrogate product should be used for these studies. Surrogate product may be actual product that will not be distributed to market or, due to cost or supply limitations; it may be product of similar density and size as the actual product. In addition, Since dosimeters cannot be placed in frozen material, any dry ice or ice packs should be replaced with surrogate material as well in order to represent the packaging configuration and areas of high density.

Examples of surrogates for Tissue:

- Rejected tissue

- Animal bones cut to the same way as the actual samples

- Artificial materials with similar characteristics such as Sawbones®

Examples of surrogates for Dry Ice:

- Pellets – something similar in density which will fill the area that will be occupied by dry ice pellets

- Blocks – something similar in shape, size and weight

Examples of surrogates for other products:

- Actual containers filled with rejected product

- Actual containers filled with material of similar density

- Empty containers if it is determined that the product does not contribute to the density

Examples of surrogates for Ice packs:

- Actual ice packs at ambient temperature

Conclusion

For frozen products packaged with high density materials such as dry ice or ice packs, reference dosimetry dose mapping studies using surrogate material at ambient temperatures result in ratios which can be used to calculate the dose required to a specific reference location in order to achieve a required dose range to the product itself. During routine production, these same ratios can be used to calculate the actual internal delivered dose to the product during routine irradiation runs.