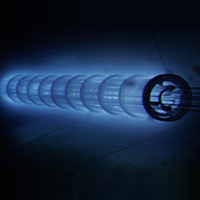

How irradiation affects the color properties of products containing glass

Glass is particularly susceptible to radiation-induced coloration/discoloration due to its amorphous, non-crystalline structure. The nature of the optical changes vary, but usually consist of coloration in the visible light region and the formation of absorption bands in the infrared and/or ultraviolet regions. The optical density is almost always increased. It is well documented, for example, that high doses of gamma radiation turn glass various shades ranging from deep brown to pale amber. Clear glass discolors when exposed to gamma irradiation, such as from a Cobalt-60 source. Ordinary flint, borosilicate, and lead glass undergo a color change from clear to light amber, brownish to black, depending on the amount of energy absorbed. Milk glass, when exposed to gamma irradiation, yields a grayish color, depending on energy absorbed and any swirling effect is highlighted, probably due to concentrations of color in the glass that have not mixed uniformly.

The actual mechanism of the formation of “color centers” has been described. The final color created is dependent on the chemical composition of the glass and can be altered by selection of additives (e.g., cerium ions can reduce browning, manganese ions induce an amethyst color). Final color is a combination of original glass color and the effects of color center formations.

Color from irradiation is considered metastable and heat, for example, is known to reverse the effect. Depending on the type of color centers formed and the hardness of the glass, varying amounts of heat or energy penetration are required to reverse color. Glass with a low diffusion rate (high softening point) is more stable. Combining all of these factors gives a very unique decorative coloration to a glass item.

Very striking color contrasts can evolve, depending upon the color of the paints utilized on an item, the chemical composition, and impurities in the glass. At low doses, the color intensity increases linearly but eventually saturates at high doses.

The final product is not radioactive or contaminated in any sense.

The general physical properties of colored glass include:

Color stability:

There is a slight loss of color during the first several days after processing, and thereafter the rate of fade is slight. The process can actually be reversed, causing the glass to become clear, by placing the unit in an oven at approximately 300°F for a couple of hours. Hence, for applications where the product is exposed to high heat or low heat on a routine basis (e.g., dishwashers), this may not be ideal.

Ultraviolet absorption:

There is a small amount of ultraviolet absorption characteristic which changes as the glass is further discolored.

Physical properties:

Other than the color change, the normal physical properties of glass are not affected.

The advantages of irradiation for decorative glass coloration include:

- Processing is done in shipping carton. There is no need to unpack or handle individual pieces.

- The process is simple, clean, and completely safe to the end product and to the consumer.

- Although economics would tend to favor large volumes, smaller volumes can also be economically attractive. The irradiation process is not dependent on processing large runs.

- There is no waste product or breakage associated with the process.

Summary

Glass coloration on irradiation is a known occurrence. The effect is not harmful to the physical properties of the glass and may be used constructively for decorative purposes.

References

- Prasil, Z and T. Marlind, “Two Colors Out of One” Glass Decoloration #125, beta-gamma 2-3/91

- Prasil, Z. and T. Marlind, “Radiation Coloration of Glass-State of the Art, Glass Decoloration #249, beta-gamma 2-3/91

- Dietz, George R., “Radiation Coloring of Glass” Presentation to Society of Glass Decorators, Annual Meeting October 11-13, 1976, Pittsburgh, PA

- Prasil, Z., E. Schweiner and M. Pesek, “Radiation Modification of Physical Properties of Inorganic Solids”, Radiation Physics and Chemistry, Vol. 35, Nos. 4-6, pp.509-513, 1990