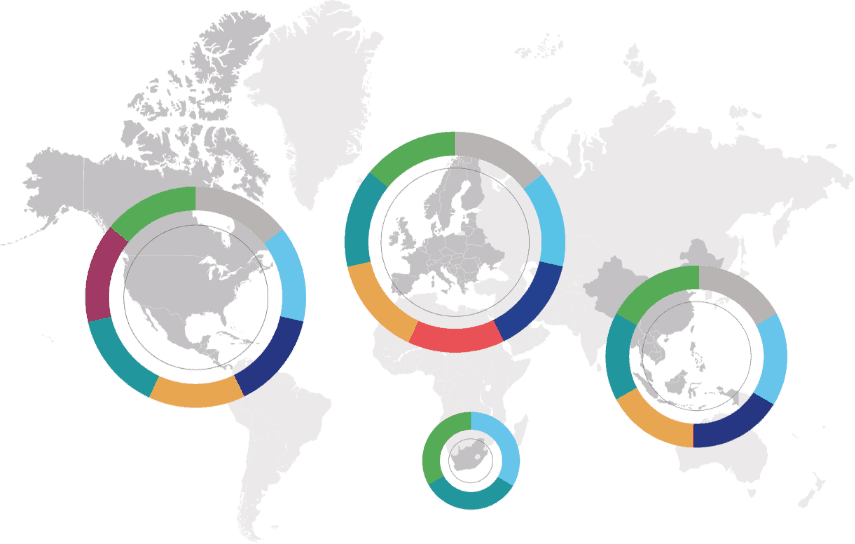

GLOBAL CONTRACT STERILIZATION SERVICES

STERIS Applied Sterilization Technologies provides contract sterilization, laboratory testing, and product and packaging testing services to medical device and pharmaceutical manufacturers.

Learn MoreOUR PRODUCTS AND SERVICES

CONTRACT STERILIZATION

Global contract sterilization and microbial reduction services using a technology-neutral offering of radiation and gas technologies.

LABORATORY TESTING SERVICES

Laboratory testing and validation services including microbiological, analytical, and product and package testing.

EQUIPMENT AND TECHNOLOGIES

Integrated sterilization equipment and control systems, including accelerators, conveyors, and automation.

RADIATION DOSIMETRY

Supports sterilization processing with both red perspex and alanine pellet dosimeters used to measure ionizing radiation.

STERILINK®

An online interactive service that provides complete real time visibility in to STERIS processing facilites.

TECHTEAM® PROFESSIONALS

Our technical professionals assist in guiding our Customers through the detailed and complex sterilization and laboratory testing processes.

Recommended Resources

View our resources to learn more about sterilization and testing services.

INDUSTRY ARTICLES

Articles produced in collaboration between STERIS AST and industry journals.

TECHTIPS

Downloadable white papers written by the STERIS AST TechTeam and other industry subject matter experts.