Sterile Barrier Integrity and Seal Strength Testing Services

What is packaging integrity testing in accordance with ISO 11607?

Packaging integrity and seal strength testing are key validation requirements for terminally sterilized medical devices, and demonstrate that the package has retained its seal strength and has no breaches or defects following sterilization, distribution, and aging.

What is sterile barrier testing?

Sterile barrier testing is used in the manufacturing of medical devices, pharmaceuticals, and other products that require a sterile barrier. This testing ensures that the sterile packaging system effectively maintains sterility throughout the product’s shelf life and the sterile barrier prevents ingress of microorganisms or contaminants to the product.

Sterile barrier integrity tests include:

Visual inspection (ASTM F1886 / F1886M)

Visual inspection testing is a method for evaluating the seals and material surfaces of flexible packaging to highlights areas of concern for subsequent tests (slits, tears, wrinkles, bubbles, channels in seals, etc.).

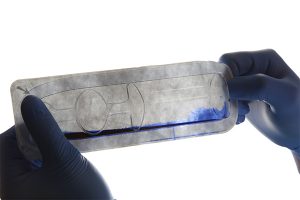

Dye penetration testing (ASTM F1929, ASTMF3039)

Dye penetration testing provides evidence that the sterile seal or surface has not been breached. Dye penetration test methods are applicable to both opaque and non-opaque materials.

Bubble leak testing (ASTM F2096) on flexible packaging

Bubble leak testing provides evidence that the sterile barrier has not been breached. In a bubble leak test, the package is submerged underwater while inspecting for a steady stream of bubbles or an ingress into the package after the test.

Bubble leak under vacuum (ASTM D4991 or ASTM D3078) on flexible packaging and rigid packaging

Bubble leak under vacuum testing provides evidence that the sterile barrier has not been breached. In a bubble leak test, the package is submerged underwater, and a vacuum is applied to the test system while inspecting for steady stream of bubbles during the test or an ingress of the test fluid into the package after the test.

What is a packaging seal strength test?

A packaging seal strength test is used to measures the strength of the seals in the packaging material to prevent the package from opening during handling and transportation. Seal strength is typically measured in terms of force required to open or peel apart the sealed layers.

Seal strength tests include:

Peel testing / seal strength / (ASTM F88 / F88M, EN 868-5 Annex D)

Peel or seal strength testing evaluates the tensile strength of seals in flexible barrier materials. This includes pouches and trays with flexible lids.

Burst testing (ASTM F1140 / F1140M, ASTM F2054 / F2054M)

Burst testing determines the ability of a package to withstand internal pressurization, pressurizing the package until the internal pressure causes it to burst.

Peel characteristics and seal width measurement (EN 868-5 Annex E)

Peel characteristics help ensure the integrity and reliability of the packaging to maintain sterility throughout its shelf life. Seal width measurement testing ensures that the seals on the packaging are of the correct width and meet the required specifications.

We also offer distribution simulation and accelerated and real-time aging services, providing our Customers with a comprehensive offering of validation testing.

Technical Support

- Our technical professionals also offers guidance toward:

- Packaging evaluations and concept reviews

- Risk assessment

- Identification of applicable standards

- Test planning and protocol development

- Evaluation of prior validations and gap analysis

Related content:

TechTalk: Product and Packaging Testing

TechTalk: Distribution Testing for Sterile Packaging and Devices